Catering Trailer

The problem:

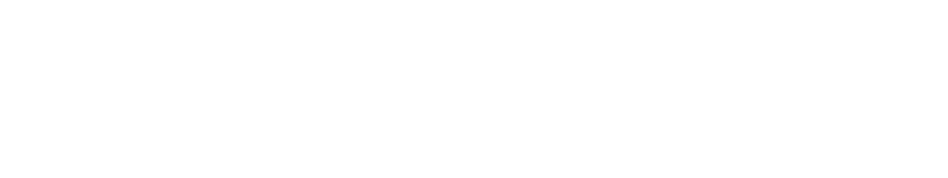

With a brand-new 14ft trailer already in-hand, the client wanted to repurpose a bare-bones generic hotdog/burger trailer to cater purely for kebabs. Starting with a thorough survey, we modelled the trailer & its existing internal provisions, along with rough representations of all the equipment required. Next we sat down with the client to work out the most efficient workflow/packaging balance. Unfortunately it quickly became apparent that none of the existing internal accoutrements were suitable. So we removed all of the existing trailer internals, leaving an empty box before getting to work on the layout. To maximise economy of space, fully fitted custom cabinetry & associated fabrications were the only option. All work was carried out with the following key attributes in mind:

- Maximise storage

- Minimise wasted space

- Minimise cleaning burden through material selection & grime trap prevention

With the detailed design phase over, drawings packs completed, components manufactured, ancillary & fixings ordered it was

time to strip out the interior & get to work building the greatest catering trailer the world has ever seen!

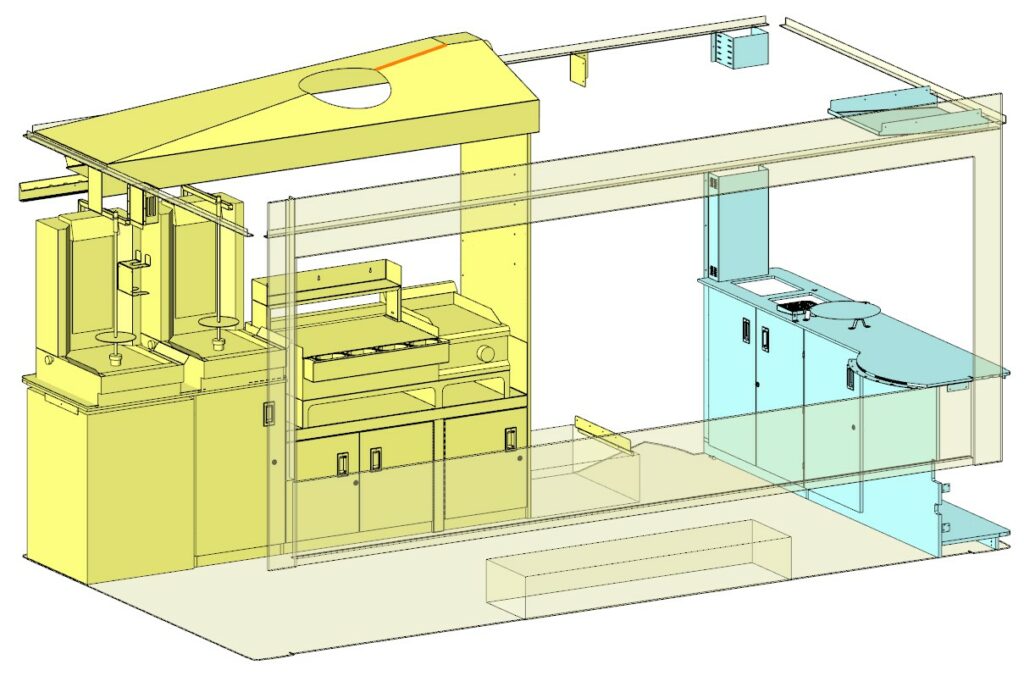

Whilst performing our survey we found that the side walls were not square with the ends of the trailer, so to ensure a perfect

fit we incorporated a round worktop joint. This enabled us to build the two mating sections of cabinetry separately, slide them

together so the joint butted together, & rotate the servery cabinetry around to meet the hatch wall for a perfect fit.

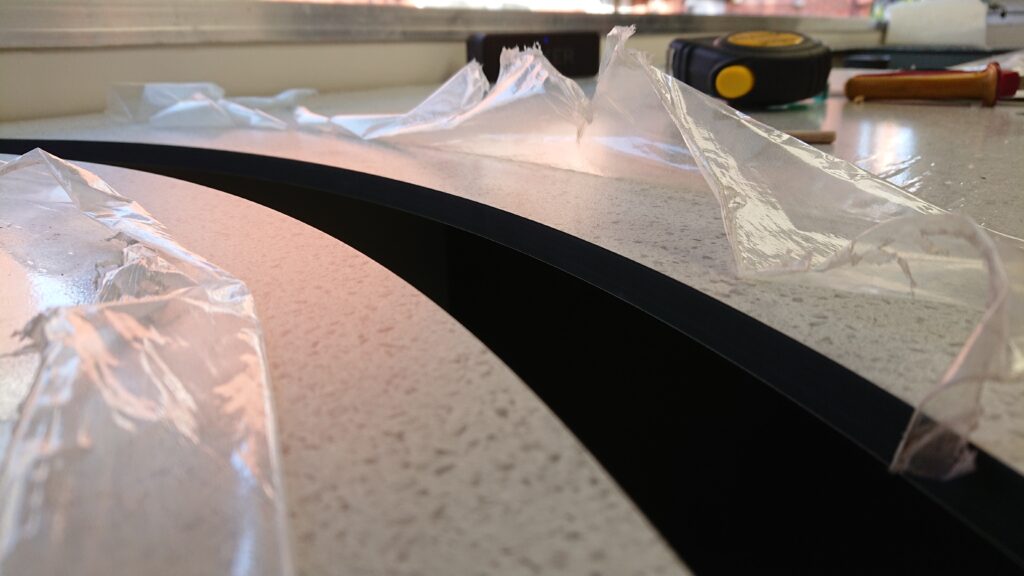

The cold servery was originally intended to be surface mounted.

Since our client wanted it recessed for both neatness & to facilitate

cleaning, we modified it by relocating the power switch & display

panel from the front to the top cover

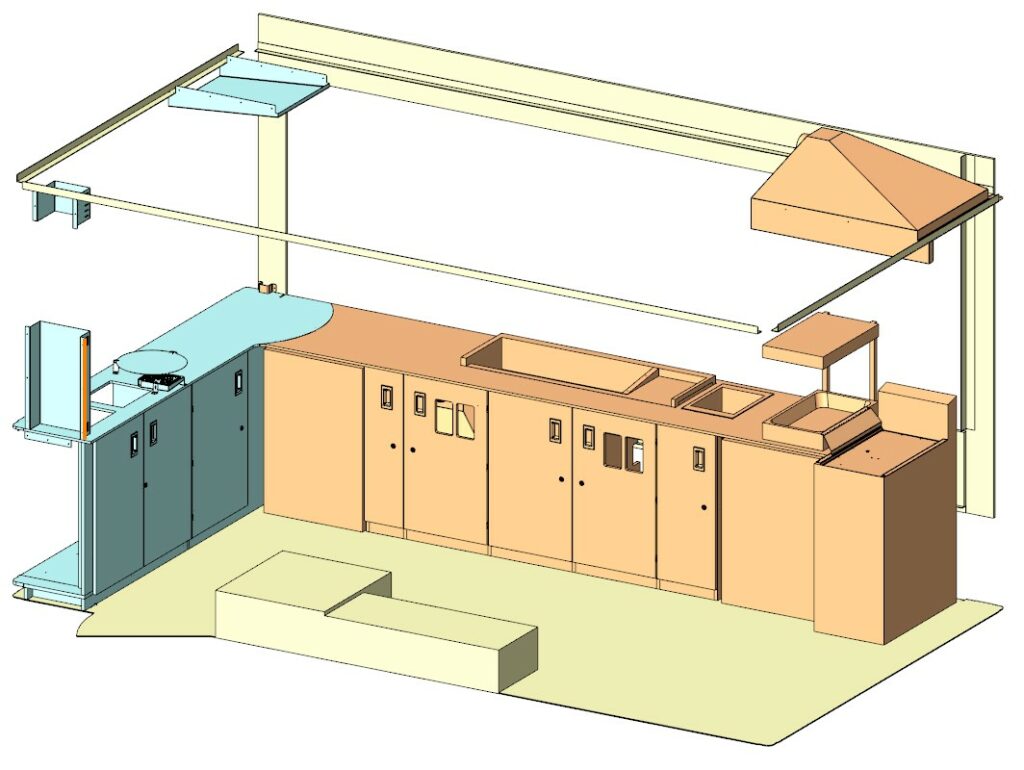

Hot end of the trailer, featuring twin basket fryer, chip scuttle, two Doner

machines, & two separate griddles to facilitate vegan options. Two

separate custom extraction systems were also included

Custom chip scuttle drain-back plate

prevents oil from the chip baskets

dribbling over the work top & down the

side of the fryer

Griddle detail. Custom stainless griddle bay designed to be assembled

with no protruding fasteners, gas pipe pass-throughs & ample access all

around to facilitate cleaning. Removable custom chicken kebab warming

rack & cantilevered gastronorm/utensil holder on front of large griddle

For more information contact us here